Weld Penetration Analysis

Weld Penetration Analysis

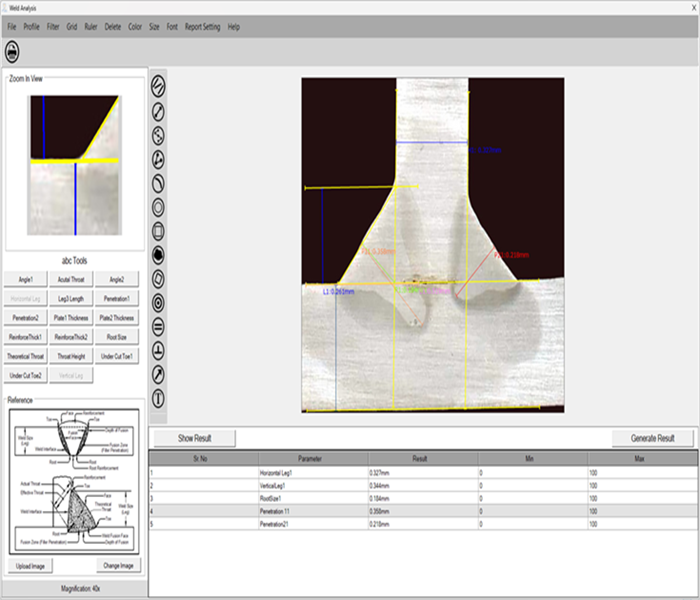

- Comprehensive Parameter Measurement:Horizontal Leg, Vertical Leg, Penetration 1 & 2, Under Cut Toe 1 & 2, Plate Thickness (both plates), Leg 3 Length, Actual Throat, Throat Height, Angles (Angle 1 & Angle 2), Reinforce Thickness (1 & 2), Root Size, Theoretical Throat

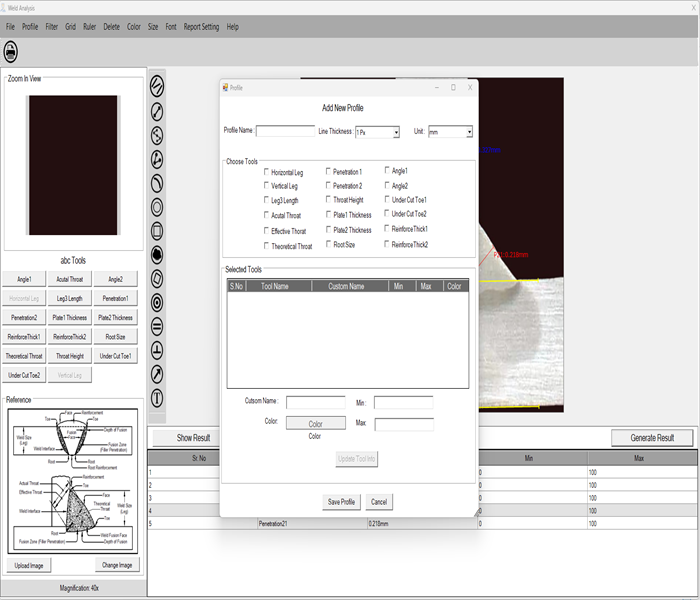

- Multiple Profile Creation:Users can create multiple profiles for repetitive analysis of similar parts, streamlining the assessment process for consistent results..

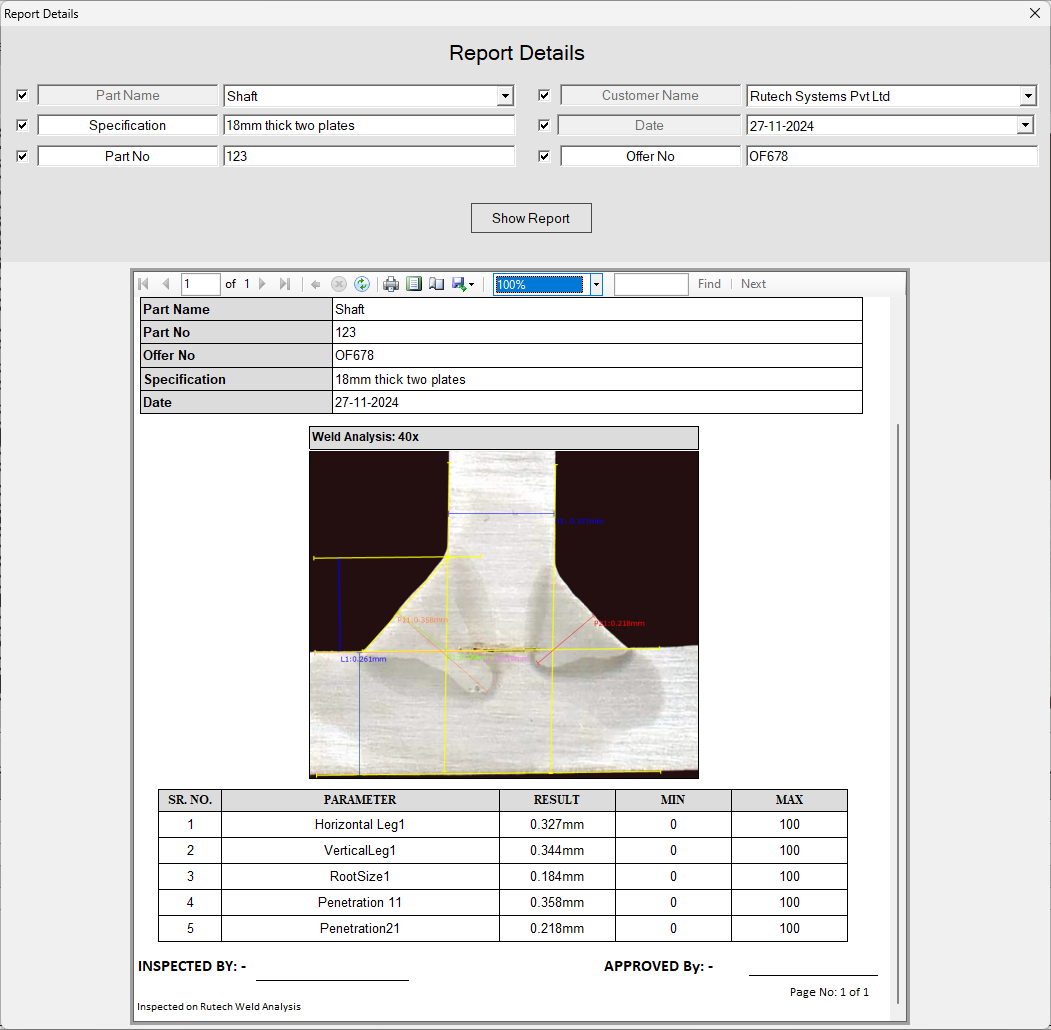

- Flexible Reporting:Reports can be generated in multiple formats, including PDF, Word, and Excel, facilitating easy documentation and sharing of results.

Weld Penetration Analysis Overview

The Weld Penetration Analysis System is designed to evaluate weld quality and integrity comprehensively. It allows for detailed measurement and analysis of multiple welding parameters, ensuring accurate assessments of weld performance. See Video..

Systems Specification

| 1. Parameters Available |

|

|---|---|

| 2. Extra Annotations |

|

| 3. Multiple Profile Creation and Customization | Users can create multiple profiles for repetitive analysis of similar parts, allowing for easy customization. |

| 4. Reporting |

Reports can be generated in multiple formats:

|

| 5. USB and Analog Camera Support | The system supports both USB and Analog cameras for capturing images. |

| 6. Full Screen Application | The application can operate in full-screen mode, enhancing user experience. |

| 7. Live and Previously Captured Image Analysis | The system allows analysis of both live images and previously captured images. |