P7.0A Full Automatic Particle Analysis System

P7.0A Full Automatic Particle Analysis System

- Fully Automatic Operation

- Versatile Sample Handling: (25mm, 47mm, 90mm)

- Motorized Sample Stage: 100mm x 100mm XY travel and 25mm Z travel

- High-Quality Imaging: CMOS USB Color Camera

- Compliance with Standards: ISO 16232, VDA 19 and ISO 4406, with options for customized standard development.

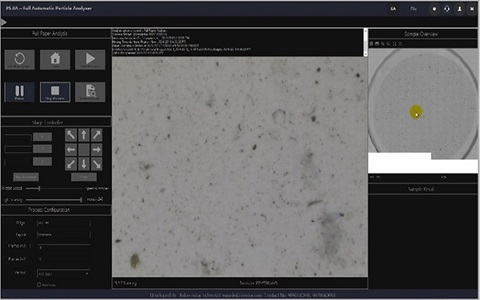

P7.0A Particle Analysis System Overview

The P7.0A is a fully automatic, precision-engineered analytical system designed for particle analysis and evaluation of components' cleanliness. It features a multi-magnification imaging system with a zoom lens ranging from 0.7X to 4.5X, ensuring high-resolution optics for detailed analysis.

Systems Specification

| Sr. No | Details |

|---|---|

| 1 | Fully Automatic. |

| 2 | Multi-Magnification Imaging Zoom lens 6.5:1 (0.7X – 4.5X) suitable for Particle Analysis with auto focus system. |

| 3 | Pre calibrated; pre-configured. |

| 4 | Software driven Ring Light Control. |

| 5 | Software driven Auto Focus and Zoom. |

| 6 | Motorized Software controlled X, Y, and Z axis sample stage with 100mm x 100mm XY stage travel. |

| 7 | Auto move to Home position and start scan position. |

| 8 | Configurable start position as per paper size. |

| 9 | One-click system from analysis to report. |

| 10 | Auto image stitching and analysis. |

| 11 | Auto save report in PDF format. |

| 12 | Four software in one system for Single field analysis, Multiple field Analysis, Full Paper analysis, and Measurement software for multipurpose use. |

| 13 | Three auto focus methods to choose from: auto focus every image before saving, multi-location pre auto focus, and pre-configured auto focus for full paper. |

| 14 | Calculation of Component-Cleanliness-Code (CCC) according to ISO 16232 and more. |

| 15 | Automatic detection of particle types: Reflective, Non-Reflective, and Fibrous. |

| 16 | Evaluation of many particle parameters for each particle (min area, max area, min size, max size, length, width, area, roundness, perimeter, Eq. Dia., Aspect Ratio, fiber length, and more). |

| 17 | Supported standards include ISO 16232, ISO 4406, ISO 4407, ISO 11218, ISO 12345, ISO 14952, NAS 1638, INF ISO 21018, NFE 48-651, NFE 48-655, SAE AS 4059, VDA 19.1, Volvo 107-0002, CAT 1E2500 (A, B, C, D, Da, E, G), and USP 788. Additional standards can be added as needed, with customization options available. |

| 18 | Extra Measurement Software Features: Projection Line, Single Line Measurement, Multiple Line Measurement, Angle Measurement, Circle Measurement, Square Measurement, Polygon Measurement, Polygon Area Measurement, Arc Measurement, Concentric Circle Measurement, Line relocation, Graphics color change, Labeling with relocation, In-built Reporting. |

| 19 | Z focusing stage: Motorized with autofocusing algorithm and 25mm travel. |

| 20 | Sample holders for 75mm x 25mm, 25mm, 47mm, and 90mm diameter filters. |

| 21 | 3W white LED bottom illumination and 8mm LEDs for top ring illumination, both software controlled. |

| 22 | Camera sensor size: 1/2” Color. |

| 23 | SYSTEM DESIGN MAY CHANGE DUE TO CONTINUOUS DEVELOPMENT OF PRODUCTS. |